We take science seriously, in our labs and beyond. It's why we've collaborated with some of the UK's leading scientists in large independent trials. The results? Symprove really works.

Come and see…

Rooted in science

Our research

Symprove has been put through its paces in several major independent studies. One, by the team at University College London saw our bacteria pass three key tests with flying colours! These set out to prove whether:

ALIVE

Symprove's bacteria are alive when they enter the body

SURVIVE

They can survive as they pass through the stomach

THRIVE

They can reach the lower gut and thrive there!

Say hello to our ingredients

Working in harmony with your body (and each other)

Live bacteria

Symprove contains four species that occur naturally in your gut. We selected Lactobacillus for its resistance to acid, and all of them for the way they work in synergy and encourage each other to grow.

Germinated barley extract

This clever grain works as a catalyst for fermentation. It helps to speed up the growth of the live bacteria, and keep the numbers steady for Symprove's shelf-life. (We source a gluten free barley, ensuring Symprove meets EU regulations).

Water

Friendly bacteria love living in water! So water, coupled with the way you take Symprove on an empty stomach, helps limit our bacteria's exposure to digestive juices that would otherwise kill them.

From the lab with love

We make Symprove in a controlled environment. We add the bacteria to a water-based solution with a gluten free liquid barley extract. Over a 21-hour period, fermentation occurs, they multiply like mad and train themselves to tolerate low pH levels in order to survive the stomach acid.

Once there's enough bacteria, we halt the process, test our samples and then get bottling.

Billions of good bugs in every bottle

Ready for a fun fact? If you lined up all the bacteria in a shot of Symprove nose to tail, they'd stretch for a whopping 30 kilometres! That's because every shot contains over 10 billion colony-forming-units of good bacteria.

Meet the scientists

Professor Simon Gaisford

UCL School of Pharmacy

Simon is Head of Pharmaceutics at University College London, and an honorary teaching fellow at the University of Manchester. During his career he's published a whopping 137 papers and four books!

Dr Frederic Moens

Research organisation, ProDigest

Frederic is a project manager in microbiome research. With a PhD in Bioengineering and Biomedical Engineering, he's also skilled in biotechnology, biochemistry, microbiology, and molecular biology. Clever stuff!

Professor Ingvar Bjarnason

King's College Hospital

Ingvar is a world leader in gastrointestinal research. He is particularly interested in holistic approaches to his work.

Getting the thumbs up from an expert

Want to hear directly from a scientist? In this handy video, Professor Simon Gaisford explains what makes Symprove different and why caring for your gut matters.

Testing makes perfect

We want to make sure that our quality and purity is spot on. That’s why our production process is patented and overseen by expert fermentation scientists. And our internal quality management systems are run to internationally-approved standards.

Love your gut – and save!

Balancing your microbiome is a marathon not a sprint. That's why it's good to try Symprove for at least 12 weeks, when 94% of people feel the difference.

Symprove blog

Ask a Dietitian: How Can I Help Manage Diarrhoea?

The Link Between Hormonal Health and Gut Health

Stress and Your Gut: A Doctor's View

Find out why over 100,000 customers choose to start their day with Symprove

Are you a healthcare professional?

We've created a website just for you. Head there for more information on our clinical research papers. Plus, educational resources on Symprove and the microbiome.

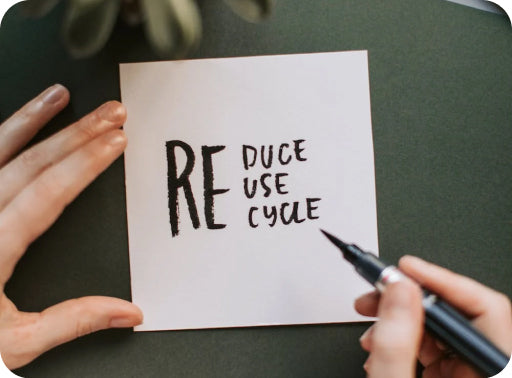

Caring for the planet

We know our planet is in crisis and take our responsibility to protect it seriously. Here's what we've done to reduce our impact so far.

We've covered Symprove HQ with solar panels

The aim is to produce 80% of our energy this way.

Our loos are flushed with rainwater

So water that would literally go down the drain is being recycled.

We've upgraded our packaging

All our bottles are made from PET plastic (the world's most recycled plastic).